Problems:-

Bio-drum Rotating mechanism not working properly. when you start drum to rotate, chain slips from driving sprocket.

On this problem we worked twice. For the first time, root causes that we found :-

Why chain slips from driving sprocket?

Because, there is no proper tension in chain drive.

Why there is no tension in chain?

Because, there are two parameters:

1. Length of chain is slightly more &

2. Alignment of Driver sprocket to the driven is not proper.

Why alignment is not proper?

Because,Driver sprocket slides over gearbox shaft.

Reasons for sliding sprocket :

a. Key in key-way is absent on gearbox shaft,

b. grub screw is not properly tighten.

Another observation is Plate on which gearbox is mounted is having slight bend centrally.

As i said that we have worked on this problem twice,

so for the first time we came with solutions that are:

1.Plate with Bend:-

As it is welded to motor mounting frame, we kept it as it is.

2.Driver sprocket alignment:-

a. Grub screw tightened,

b. we used wooden key for the key-way on Gearbox shaft.( Temporary solution)

3. Length of chain:

we made an arrangement so that we can increase or reduce the tension in chain drive. With the help of hollow cylinder (small) & shaft over which it rotates(sorry i don’t have any images of it).

Finally, mechanism runs properly and no slippage of chain from driving sprocket.

*********************************************************************************

Mistake:

we told the person who is working on this project to insert a metallic key in a key-way.

This suggestion made me to work twice on this mechanism.

**********************************************************************************

Because this person is not working continuously in Vigyan Ashram, so he gave this task to one of student from ashram. He fitted metallic key but while doing this due to hammering Grub screw gets sheared and driving sprocket get offset from driven sprocket and again alignment is disturbed.

Due to shearing of Grub Screw sprocket get fitted on the shaft permanently.

While working second time:

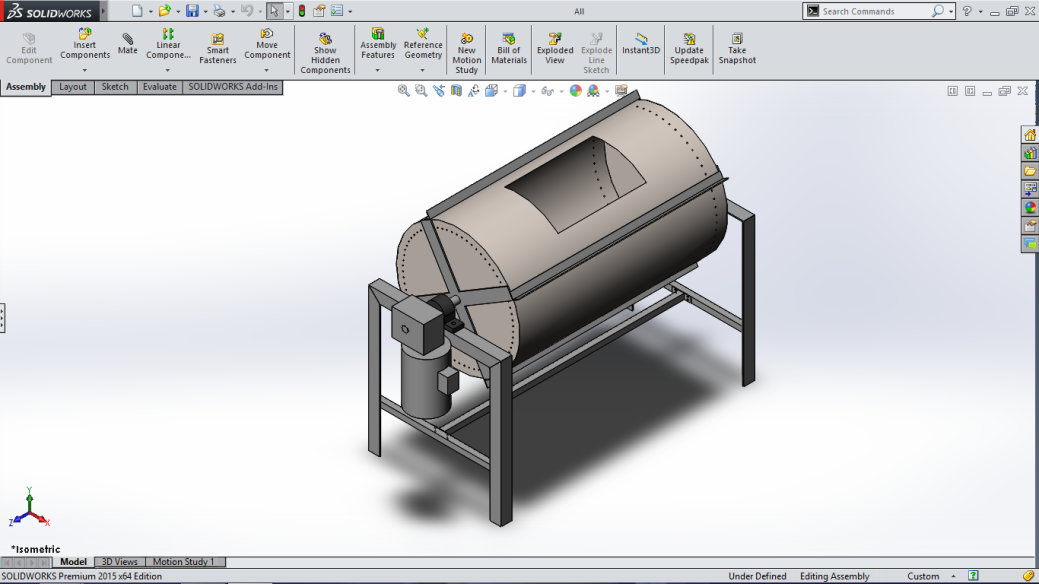

- we disassemble all the parts from mechanism i.e. Motor, gearbox etc.

- With the help of drill machine we made a slot on the plate which is welded to motor mounting frame. Due to slot it is easy to move gearbox on the plate horizontally. alignment of Driving sprocket with driven is becomes easier.

- Reduce Length of the chain by removing linkages.

- Gear box is lifted to a certain height so that the tension in drive is proper. we used wooden plate to lift gearbox from welded plate. This wooden plate will absorb vibrations if any.

- For the proper alignment of motor and gearbox, motor is also lifted with the help of washers.

From last few days it works properly without any disturbance so it is now on site testing.